"Gundam" aerial work car robot - for railway equipment maintenance

2024-07-12 16:10"Gundam" aerial work car robot - for railway equipment maintenance

The new robot, developed by Nishi JR in collaboration with robotics developer Jinki Ittai Co and infrastructure IT and electrical company Nippon Signal Co, is described as a "multi-functional railway heavy machinery for railway equipment maintenance". Mr Nishi said the project was needed because "there is a Labour shortage for infrastructure maintenance work, not just railways".

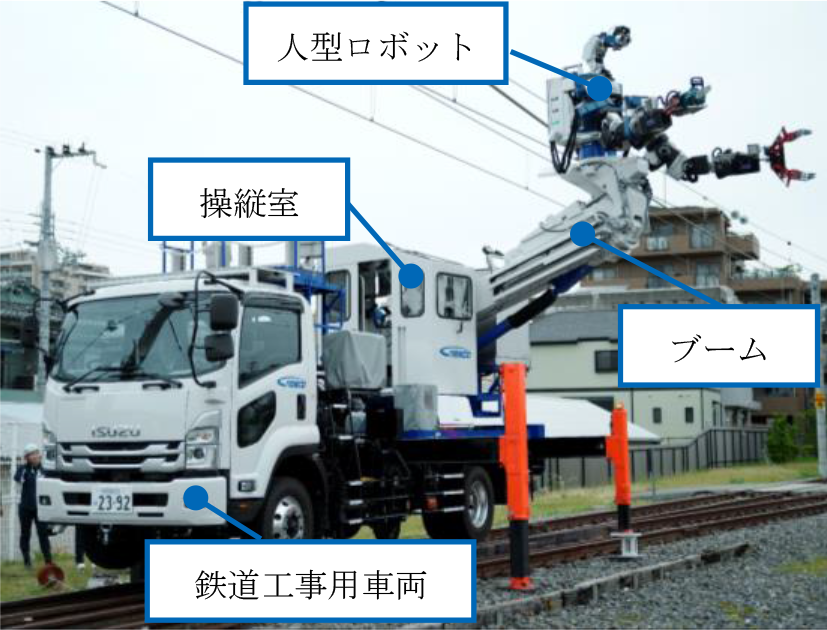

The new aerial vehicle robot is carried by a railway aerial vehicle with a control room on the vehicle and the robot is located at the end of the telescopic arm, and its main purpose is to reach the overhead power lines to repair problems remotely.

It can carry a maximum weight of 40 kilograms and operate remotely at a height of 12 meters above the ground.

In fact, this mechanical equipment appeared as early as March 2022 at the International Robot Exhibition, which is a fusion of heavy equipment robots and multi-functional railway heavy equipment. The equipment is composed of three parts, which are: zero man-machine ver.2.0, man-machine operator ver.5.0, and special aerial work platform car.

Overall, the robot's system is equipped with an independently developed force control technology that accurately controls the force of the electric actuator, as well as bilateral control technology. The system is very simple. The operator sits in the cab and uses the HP Reverb G2 VR headset to observe construction from a robotic perspective. A large control panel is used to operate two robotic arms equipped with double clamps, allowing the user to interact in detail with a variety of machinery. At the same time, the operator will be able to feel the weight of the object while working, achieving "human-machine linkage".

Of course, this "zero man machine ver.2.0" can do much more than that. The new aerial robot can mainly help solve two problems. First, safety, for example, after the robot replaces the manual operation, the number of people who need to climb the overhead catenary can be reduced, and industrial accidents such as falling can be avoided. The second is to improve work efficiency and save manpower to cope with the problem of a reduced labor force, which according to West Japan Railway Company, most tasks require at least 30% less labor.

West Japan Railway said the new equipment will also be used to cut down trees or remove other obstructions, paint infrastructure and replace or repair signal hardware. "Mechanization will greatly help eliminate workplace accidents caused by electric shock or falls, while also improving safety."